Electricity and Energy in Wastewater

- Jarret Choy

- May 28, 2024

- 2 min read

An aspect of wastewater treatment that is often overlooked is the role of electricity. Globally, pumping systems account for over 20% of all electricity. This means that wastewater treatment plants require a massive amount of energy to continuously run. Aside from teaching plant operators how to conserve energy, there are other methods and equipment that optimize electricity.

Some of the more obvious solutions to reducing and saving on energy consumption, are to install processes that naturally use less energy, and turn equipment on only when it’s necessary. In most cases, the equipment requires 24 hour use, so optimizing the equipment allows the plant to cut down on operating costs and increase efficiency.

A few ways to optimize equipment are listed below:

The use of Variable Frequency Drives (VFD’s) is one of the best ways to increase the efficiency of the pump and reduce costs. With the addition of a VFD, operators can adjust motor speeds and other aspects of the equipment to match real-time demand.

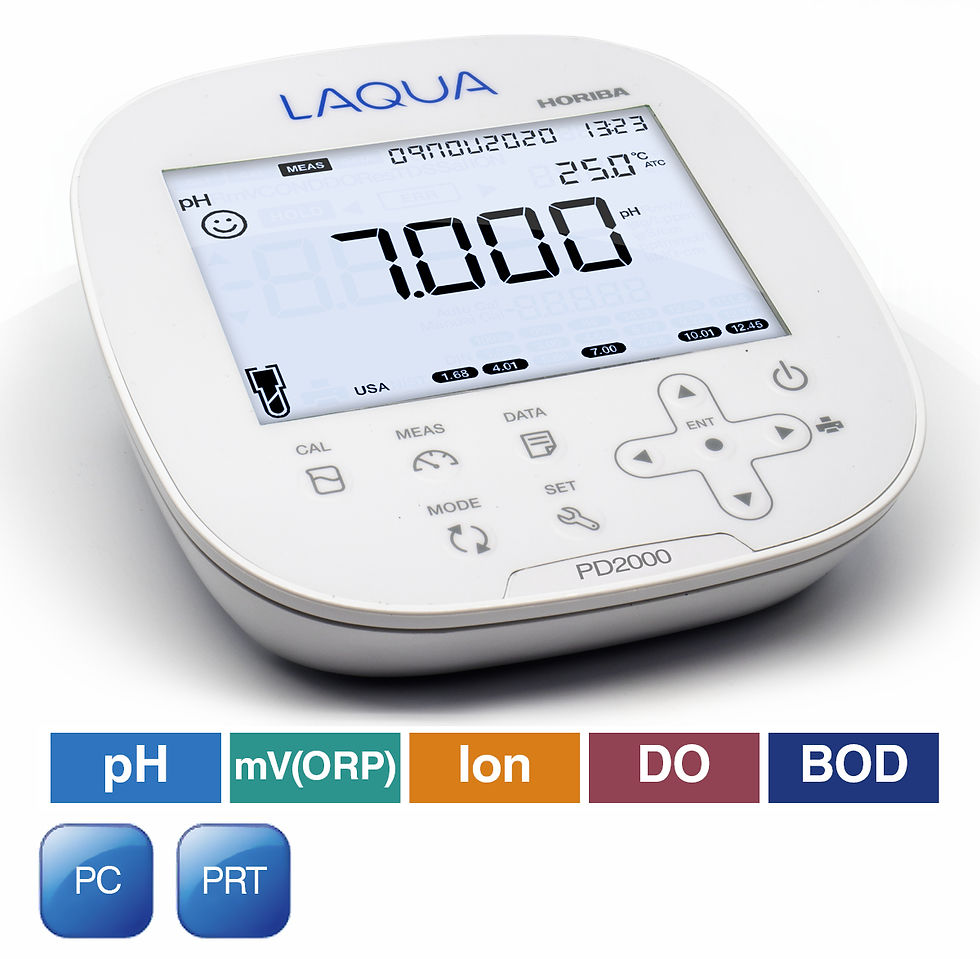

Another piece of equipment are monitoring systems for processes like aeration and sludge handling. These too offer versatility as operators can change the equipment if needed.

Regular maintenance is also a great way to cut energy costs. By keeping the equipment in constant good working condition, equipment is going to run at its full capacity. Any downtime leads to a less efficient treatment process and fixing up equipment is an expensive task.

Being conscious about energy use is especially important in the wastewater industry as pumps require high amounts of energy. It’s good to know where energy flows to and from, and how we can minimize the use of this valuable and expensive resource.

Comments